Test steps of bag method sampling cabin for interior parts

-Dongguan City Environmental Instrumentation Instrument Co., Ltd.

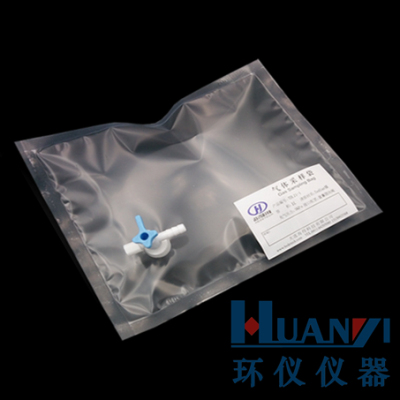

Product name: Bag method sampling cabin for interior parts

Meet the standard: CVTC 54072—2015 "Test Method for Volatile Organic Compounds and Aldehydes and Ketones in Vehicle Interior Parts (Bag Method)"

1. Test steps

1.1 Blank cleaning of sampling bag

1.2 Set the temperature of the walk-in high and low temperature test chamber to 80 ℃, open the door and turn on the gas circulation for 30 minutes, and close the door.

1.3 Cut the gas sampling bag to be cleaned, put the sampling bag inside out, put it into the test chamber, reopen the door after heating (10-12) h, and replace the gas in the chamber for 30 minutes.

1.4 Turn the gas sampling bag over, close the door, and continue heating (2~3) h.

1.5 Take out the gas sampling bag, turn the inner surface back, and use a sealing film machine to seal the gas sampling bag.

1.6 Use a diaphragm vacuum pump to evacuate the gas in the gas sampling bag and observe its air tightness (a certain amount of nitrogen can be filled, and after 2 hours, observe whether the sampling bag is significantly reduced to determine the air tightness of the sampling bag).

1.7 Use high-purity nitrogen to replace the gas sampling bag, fill it with high-purity nitrogen about 50% of its volume, and then extract the gas. Repeat the operation 3 times.

1.8 Accurately fill in 50% high-purity nitrogen, heat at 65 ℃ for 2 h ± 10 min, use TENAX tube to capture benzene and DNPH tube to capture aldehydes. The capture conditions are shown in the table.

1.9 Verify that the bag is blank on the computer, and all individual substances are required to be less than the detection limit of the method.

1.10 If not satisfied, repeat the above steps.

Manufacturer: Dongguan Huanyi Instrument

Capture condition diagram