How to solve the problem of hot and cold shock test chamber prone to generate static electricity

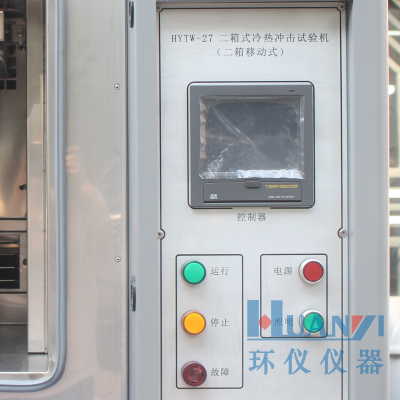

The thermal shock test chamber is an indispensable test equipment in the metal, plastic, rubber, electronic and other material industries. It is used to test the material structure or composite material, and it can withstand the continuous environment of instantaneous extremely high temperature and extremely low temperature. The chemical change or physical damage caused by the thermal expansion and contraction of the sample can be detected in a very short time. The hot and cold shock test chamber is prone to static electricity during use, how to solve it?

1. Suppress the occurrence of static electricity: The source of static electricity is the friction and separation between objects. These effects must be suppressed as much as possible. For example, in operations such as liquid pipeline transportation, dust air transportation, and plastic extrusion, the method is to reduce the speed. In fact, this will affect operational efficiency. The safe flow velocity of petroleum products does not exceed 1m/s. Static electricity differs in charge or polarity due to different substances. Therefore, a feasible measure is to avoid the use of insulators that are easy to be charged in the cold and thermal shock test chamber, and use a combination of materials that are easy to generate static electricity.

2. Promote hot and cold shock test chamber the leakage of charge: In disaster countermeasures, the simpler method is grounding. This method quickly dissipates the charge through metal conductors. However, with this method, if the charged body is oriented, it can be easily eliminated, while the plastic, chemical fiber, petroleum and other insulators have little effect because the charge of the charged part is difficult to move!

3. Leakage charge of additional conductive substances in the object: including metal powder and carbon black added to the tires and workers' boots and the floor materials of chemical plants, and the use of hydrophilic oils in chemical fibers and plastics to prevent electrification . Increase the relative humidity in the air, form a water-absorbing layer on the surface of the object, enhance conductivity, and hardly become charged at a humidity above 80%. Therefore, in places that may be charged, humidity can be increased by adjusting humidity devices and sprinkling water. But the problem is that people may feel uncomfortable or have an adverse effect on equipment and products.